Cellular Manufacturing

Cellular manufacturing gives you an enormous value through production efficiency that ensure products are manufactured at the highest quality and lowest price.

As part of our precision machining services, our cellular manufacturing process allows us to execute high volume jobs in a flexible, responsive manner. This lean manufacturing method minimizes waste and improves quality, scheduling, and equipment efficiencies.

Benefits of Herker's Cellular Manufacturing

- Cost effective

- Quality, precision machining

- Large volumes

- High on-time delivery

- Low scrap

- Low variability

Cellular Manufacturing Case Study: Gage Wheel Arm Assembly for Agricultural Application

Overview

We created a dedicated one-piece flow cell for the gage wheel arm assembly. Utilizing work-holding arrangements to set up multiple parts at a time, a shaft blank is gun drilled, stamped sleeve is pressed on, and strap is welded. The high volume cell incorporates many independent processes and combines them into one. This successful method allows us to adjust to variable volume demands and reconfigure quickly to produce a different product just as efficiently as the first was.

The Result

Time and cost reductions are realized with removal of batch manufacturing. Throughput can be increased simply by adding more personnel.

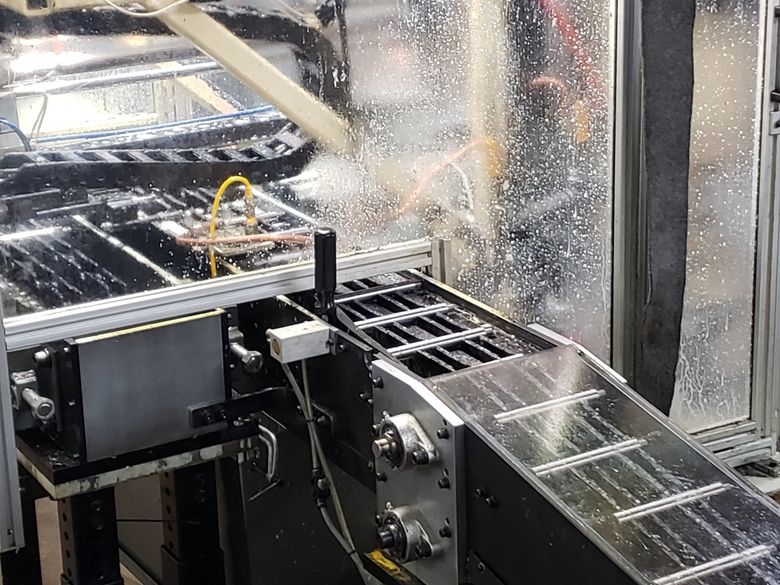

Cellular Manufacturing Case Study: Lapping of Hydraulic Piston Shoes for Hydraulic Pump Application

Overview

A lapping machine cell was dedicated to produce hydraulic piston shoes through an efficient, controlled process. The cell prevents parts from being damaged in transit between operations by allowing us to take finish machine blank, lap and pack in one area by one team.

The Result

Improved hydraulic piston shoe quality through streamlined production.

Cellular Manufacturing Case Study: Shaft Coupling

Overview

We designed a shaft coupling cell to achieve our customer's demanding 24-hour, order to shipment, turn-around requirement. To create the cell we used two existing CNC lathes and purchased a keyseater and CNC machining center. In the process, a casting is bored to within a .001 tolerance, keyway is machined, two holes are drilled and tapped, set screws are inserted, and the finished part is individually packaged and labeled.

The Result

Quality parts are efficiently manufactured, assembled, packaged and shipped on time.